あなたのためにありがとう

注目 イェセングについて !

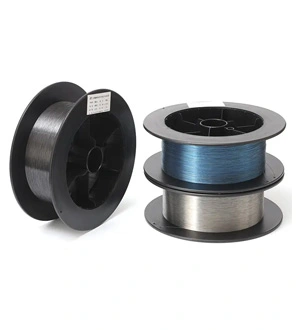

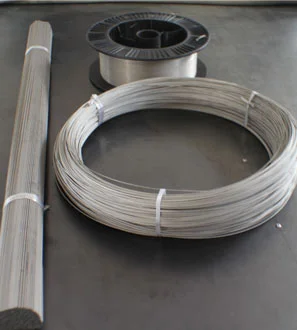

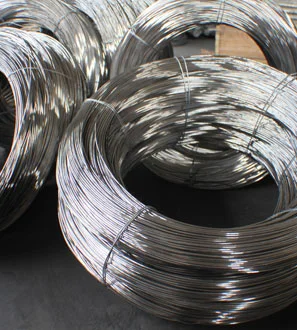

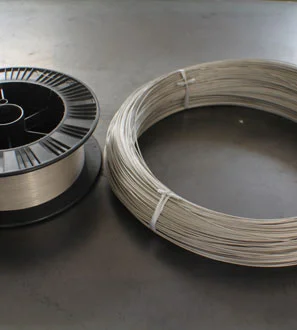

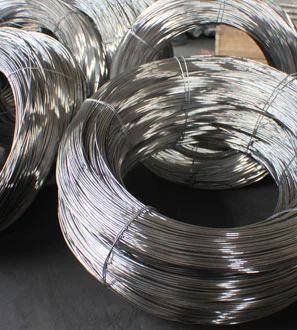

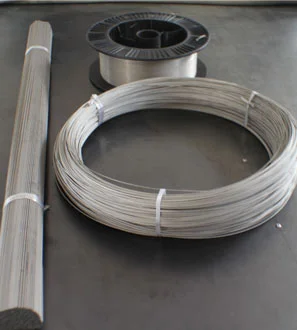

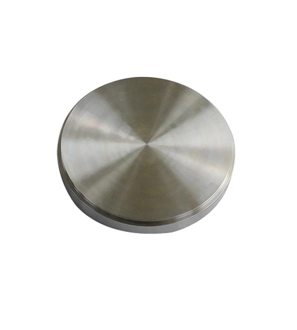

チタン溶接ワイヤ 贩売のための株式

チタン溶接ワイヤの概要

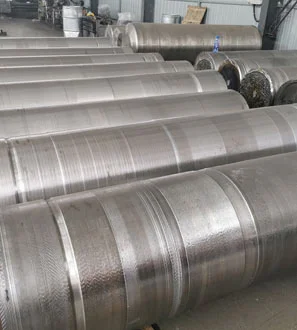

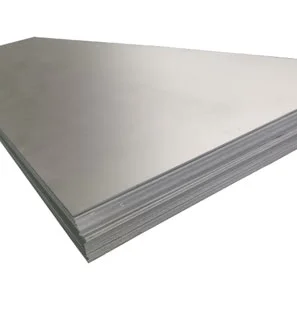

純粋なチタンまたはチタン合金から作られたYeshengチタン溶接ワイヤは、プレミアム溶接ワイヤ製品です。 航空宇宙、医療、化学処理、海洋、および自動車産業では、これらの溶接ワイヤは、さまざまなチタン部品やコンポーネントを結合するために頻繁に使用されます。 Yeshengチタン溶接ワイヤの高強度、耐食性、および卓越した溶接能力により、人気があります。 お問い合わせ競争力のあるチタン溶接ワイヤー価格!イェシェンティはチタンワイヤーサプライヤーカスタムの選択については、ここをクリックして詳細をご覧ください。

チタン溶接ワイヤの特徴

-

1

高強度: チタン溶接ワイヤは非常に高い強度対重量比を持ち、多くの高性能アプリケーションに理想的な材料となっています。

-

2

耐腐食性: チタンは、海水、酸、アルカリ性溶液など、さまざまな環境での腐食に対して非常に耐性があります。

-

3

低熱膨張: チタンの熱膨張係数は非常に低く、寸法安定性に優れています。

-

4

高融点: チタンは融点が高いため、高温の用途に適しています。

-

5

優れた電気伝導率: チタンは優れた電気伝導率を持っているため、電気用途での使用に最適です。

-

6

軽量: チタンは軽量であるため、重量が重要な要素であるアプリケーションでの使用に適しています。

-

7

生体適合性: チタンは生体適合性があるため、医療用インプラントでの使用に最適です。

-

8

非磁性: チタンは非磁性であるため、磁場を避けなければならないアプリケーションでの使用に理想的です。

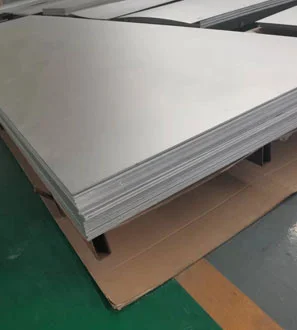

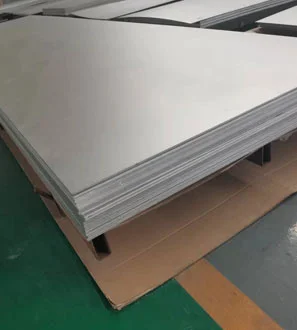

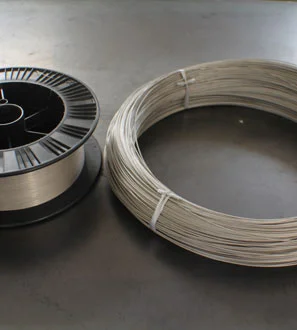

Titanium Weld Wire Specification

| Product Name | Titanium wire |

| Grade | GR1, GR2, GR5, GR5ELI, GR7, GR9, GR12, GR23, Ti-4Al-2V, Ti-4Al-1.5Mn. |

| Size | Diameter 0.02mm-5mm or as your request |

| Standard | ASTM F1341-1999, AMS4951-2003, AMS4954-2003, BS2TA28:1974, GB/T3623-2007, GJB2219-1994, ΓOCT27265-87, JISH4670-1993, DIN17863-1973 |

| Brand Name | Yesheng |

| Application | chemical industry, Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability, High strength and light weight. |

| Technics | hot rolled and cold rolled, extruded. |

| Surface | Annealed surface, pickled surface, bright surface. |

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2015; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

Welding method of titanium welding wire

Welding titanium welding wire is a critical process that demands precision and expertise due to the unique properties of titanium alloys. Several welding methods are available for working with these materials, each with its own advantages and considerations.

Gas tungsten arc welding (GTAW), also known as TIG (tungsten inert gas) welding, is one of the most commonly used methods for welding titanium alloys. It is favored for its ability to produce high-quality welds and its versatility in achieving good results. TIG welding is known for its clean and precise welds, making it a preferred choice in aerospace, medical, and high-performance applications.

Gas metal arc welding (GMAW), or MIG (metal inert gas) welding, is another commonly used method for welding titanium. It is especially suitable for certain situations, such as when high deposition rates are required. This method offers efficiency and ease of use while ensuring strong and reliable welds.

Other methods, like resistance welding, plasma arc welding, and electron beam welding, can also be used for titanium alloys but are relatively limited in their applications.

Additionally, more advanced techniques like laser welding offer benefits in terms of speed and precision, making them suitable for specific requirements.

In summary, the welding method for titanium welding wire is carefully selected based on the specific needs of the application, taking into account factors like material thickness, joint configuration, and the desired weld quality. Each method has its unique strengths, allowing for tailored solutions in various industries, including aerospace, medical, and high-performance manufacturing.

Manufacturing quality certifications for titanium welding wire

Manufacturing quality certifications for titanium welding wire are essential to ensure the reliability and performance of this crucial material in various industries. Titanium welding wire is a vital component used in welding titanium alloys and custom titanium products, and adhering to stringent quality standards is paramount.

Certifications for titanium welding wire manufacturing typically include compliance with industry-recognized standards such as AWS A5.16. This standard specifies the requirements for titanium and titanium alloy welding wire, ensuring that it meets precise composition and quality specifications. The different grades, such as ErTi-2, ErTi-3, ErTi-5, ErTi-7, and Er-12, adhere to these standards, reflecting the specific alloy composition and characteristics suitable for distinct applications.

Quality certifications are a testament to the commitment of manufacturers to maintain consistency and precision in the production of titanium welding wire. These certifications ensure that the material meets the demands of critical industries like aerospace, medical, and high-performance manufacturing, where precision, reliability, and performance are non-negotiable.

Having the appropriate quality certifications guarantees that titanium welding wire aligns with the stringent requirements of industries, reinforcing its value as an indispensable material for welding titanium alloys, and ensuring that it delivers the expected performance and longevity in critical applications.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский